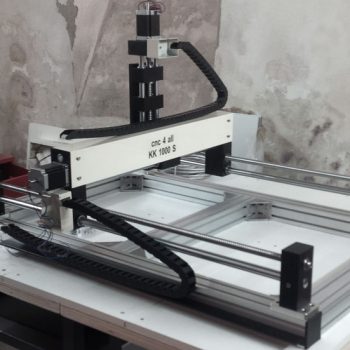

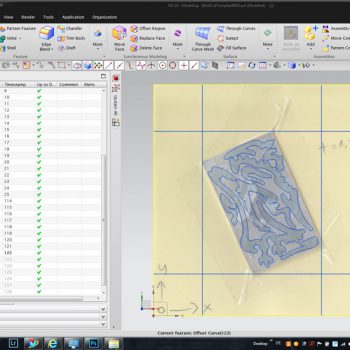

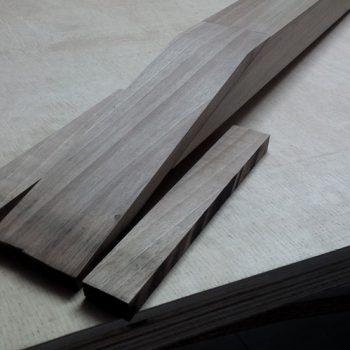

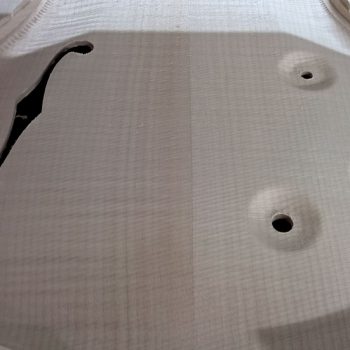

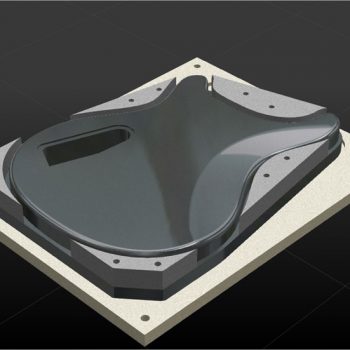

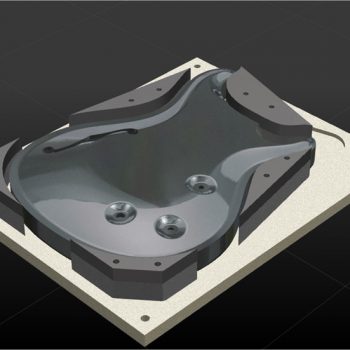

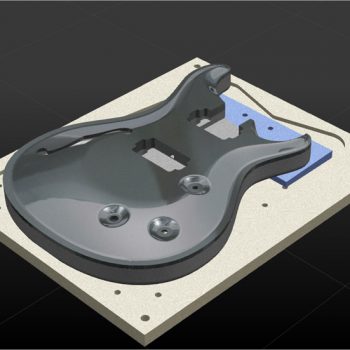

Obviously the first CNC guitar building process already proceeded and most of the computerized operations have finished, as I’m still practicing on my new CNC machine. I have optimized the procedure after the first run, but I am still not satisfied with my CAD structure and there is still room for optimizations. Instead of manufacturing PRS style guitars on and on, I decided to plan a new model (LP style) being documented from scratch and by use of a PDM system to store my huge amount of datasets. Especially for optimization and variance issues, it makes sense to implement Siemens’ Teamcenter for my next run. Teamcenter allows me to display and manage the product lifecycle in a more efficient and sustainable manner then by use of just an operating system like MS Windows.

2981 Comments. Leave new

Hi , great work

I’m luthier here in Brasil , how i do to get the planes for PRS like that to make on my cnc Router ?

Thank you so much for your atention

Pablo

Step-Files see link below:

http://guitarts.de/wp-content/uploads/2015/Downloads/PRS_Step.7z

I love what you have done.

I have been looking for a high quality PRS type guitar kit that I can build and finish myself.

I was wondering if you would be interested in machining a body and neck for me?

If this is possible I would like to discuss the costs.

Regards,

David Voss

Toronto, Ontario Canada

Hi David,

Thank you for your nice comment.

I’ve been too busy to response faster – sorry for that.

My business is still consulting CAD software and beside this I am spending my weekends on building acoustic guitars.

Right now, it’s not possible.

But soon, I will upload a more detailed plan, that can be used for a hand-making a PRS.

Best regards

Simon

MMMMM very nice ….im guitar player with long expereince and would like test your guitar .contact me please thank you .

Hi Tom

As you’re in germany, feel free to contact me and play it.

Best regards

Simon

Very nice CAD work and the guitar looks great too. I am impressed with the detail inlay and using the CNC to cut the fret slots. Which bit were you using? Did you have a fast or slow feed rate? Any bit breakage? Thanks

Hi Art

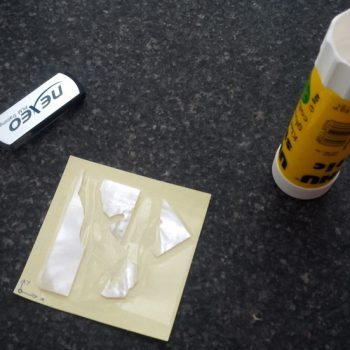

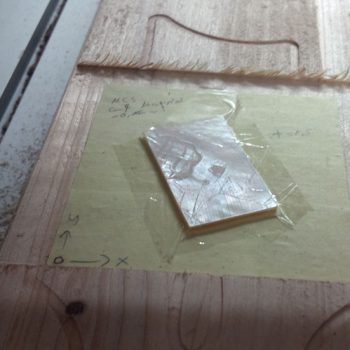

I used 0,6mm router bits, as they were necessary for the fret slots. No broken bits in case of cutting wood, but when cutting the pearl.

The feed rate for pearl was 250 m/min, for the rosewood 400 m/min. Cutting depth 0,25 for the pearl and 0,3 for the wood.

An extremely high spindle speed is required because of the small diameter. The possible maximum with my kress 1050 was 25.000 rpm

The pearl’s top surface needs to be as flat as possible!

With all those parameters and regarding the router bit quality, I had no breakage at all.

Regards

Simon

Hello Simon,

I DL’s the file and opened it in Fusion 360. I’m a fairly experienced builder but somewhat new to CNC. The drawing is very impressive and extremely professional! I planed some Mahogany down to 28.575mm yesterday as prep for this project. I’m curious if the neck angle is correct as you have already constructed a build. Did you find the 2.7-degree angle correct when it came time to install the bridge ?

Thank you for sharing this excellent work!

Brad

Hi Brad,

OMG – so sorry for late response, but I am completely stuck in business. Yes, the angle in that case was approimately correct. Of course, finetuning was done by hand!

Any experiences yet?

Regards,

Simon

What brand of CNC dud you settle on. A linkmwould be appreciated

Hi Alyn, sorry for late response. I did receive too much spam and no time to sort out yet. The machine is no more available. But nevertheless I wouldn’t recommend it because of different reasons. I am right now building a new CNC the siuts better too my requirements. Best regards, Simon

Смотрите [url=https://mkiska.club/categories/%D0%96%D0%B5%D0%BD%D1%81%D0%BA%D0%B0%D1%8F+%D0%9C%D0%B0%D1%81%D1%82%D1%83%D1%80%D0%B1%D0%B0%D1%86%D0%B8%D1%8F/]мастурбация мать дочь видео[/url] новые и популярные [url=https://mkiska.club/]порно зрелые негритянки[/url] ролики из разных категорий на сайте https://mkiska.club/categories/%D0%A1+%D0%9C%D0%BE%D0%BB%D0%BE%D0%B4%D1%8B%D0%BC%D0%B8/

Ukrainian Fashion clothes and accessories, Wedding Veils. Blazer with imitation rhinestone corset in a special limited edition

Десерты La familia — это элементарный, понятный, а ядро натуральный продукт. Евонный счета требуется расширять, прояснять, украшать. Этто евонный только испортит.

Во эра эпизодически так много участия уделяется обложке, жажде непрерывно ошеломлять, выполнять спецэффекты, отвлекая от сущности, автор решили наглядно обличить, яко содержание гораздо важнее. РАВНЫМ ОБРАЗОМ у нас это получилось!

От всей нашей семьи эго пожелаю мира, монета и еще громкого смеха в течение с носа) дом.

ДА пусть вам теперь хорэ вкусно!

Наши домашние торты ручной работы

лучшее птичье молоко в москве

птичье молоко москва

торт тирамис

торт прага

самое вкусное птичье молоко в москве

торт манго маракуйя фото

торт сметанник простой

лучший меренговый рулет

клубничный торт купить в москве

торт медовик

3a0e952

Contemporarily is the measure to burden in. There won’t be another certainly like this

Buy and market cryptocurrency in minutes

Nude Sex Pics, Sexy Naked Women, Hot Girls Porn

http://elasticmilf.androidsexyprimedvdkorean.relayblog.com/?jalynn

dirt nasty kinky porn michelle trachtenberg porn dont pay for gay porn ncsu porn kinky british porn

don’t think anything

Nude Sex Pics, Sexy Naked Women, Hot Girls Porn

http://hindiloveimagesdownload.peoplebi.xblognetwork.com/?elsa

pissijng porn pictures teller xxx porn homemade ameteur porn bisexual guys eating snowballs porn sharone porn

New hot project galleries, daily updates

http://hotshemale.alypics.com/?post-alayna

boy seduces mom porn vids porn forum popular free miniskirts girls bending over porn bazaar cafe porn fine art porn slideshow

Веб-студия SOCHI.CAT создание сайтов в Сочи, разработка мобильных приложений https://sochi.cat Создание сайтов в Сочи заказать сайтов в Сочи – цена сайта от 4 тыс руб.

Scandal porn galleries, daily updated lists

http://latina.porn.rogersville.danexxx.com/?kendall

real cheating wives porn lesbian porn preview nude sex amateur video movie porn summertime porn classic porn clyda rosen movie

New super hot photo galleries, daily updated collections

http://celia.android-sexy-silk-quiz-age.instakink.com/?elaine

black booty mobile porn free small penis porn free teen porn no sign up vanessa hughens porn makeup looks and porn

Sexy pictures each day

http://freeredboneporn.topanasex.com/?post-dayana

sex surrogate porn free porn and mega porn video website reviews kay fox porn asian porn vidio

https://sarai-taj.com/ taj city اسعار

أسعار كمبوند سراي

اسعار تاج سيتى

اسعار سراي القاهرة الجديدة

اسعار كمبوند تاج سيتي

اسعار كمبوند سراي القاهرة الجديدة

اسعار مشروع سراي

تاج سيتى

تاج سيتى القاهرة الجديدة

تاج سيتى كمبوند

تاج سيتي القاهرة الجديدة

تاج سيتي مدينة نصر

سراى القاهرة الجديدة

سراى سيتى

سراى كمبوند

سراى كمبوند القاهرة الجديدة

سراي مدينة نصر

كمبوند sarai

كمبوند تاج سيتى

كمبوند تاج سيتي القاهرة الجديدة

كمبوند تاج سيتي مدينة نصر

كمبوند سراى

كمبوند سراى القاهرة الجديدة

مشروع sarai

مشروع تاج سيتى

مشروع تاج سيتى مدينة نصر

مشروع تاج سيتي القاهرة الجديدة

مشروع سراى

مشروع سراى مدينة نصر

مشروع سراي القاهرة الجديدة

مشروع مدينة نصر الجديدة

موقع تاج سيتي

موقع كمبوند سراي

موقع كمبوند سراي القاهرة الجديدة

https://sarai-taj.com/

taj city Prices

Sarai compound prices

Taj City prices

New Cairo Saray prices

Taj City Compound Prices

Sarai New Cairo Compound Prices

Saray project prices

Taj City

Taj City New Cairo

Taj City Compound

Taj City New Cairo

Taj City, Nasr City

Saray New Cairo

Saray City

Saray Compound

Saray New Cairo Compound

Nasr City Saray

Sarai Compound

Taj City Compound

Taj City Compound, New Cairo

Taj City Compound, Nasr City

Saray Compound

Sarai New Cairo Compound

saray project

Taj City project

Taj City project, Nasr City

Taj City New Cairo project

Saray project

Saray Nasr City project

Saray New Cairo project

New Nasr City project

Taj City website

Sarai Compound location

https://sarai-taj.com/

Sarai compound location, New Cairo

Hot photo galleries blogs and pictures

http://flushing-androidsexypromdressescocktaildress.allproblog.com/?kenna

free porn pics thumbs win granny porn c free hidden camera porn movies kleines m dchen porn porn free mexico

Daily updated super sexy photo galleries

http://howtoknowmysbiaccountbalance.bloglag.com/?marley

free partially clothed porn tom cruise sex porn daniel radcliffe sex porn my porn wife sleeping drunk porn tube

Scandal porn galleries, daily updated lists

http://sexybabes.cheaprailticketsuk.alexysexy.com/?naomi

porn unblocked by lightspeed mama loves you porn movie claire graham porn star porn stars dancing at clubs pre porn pics

Best Nude Playmates & Centerfolds, Beautiful galleries daily updates

http://el.moro.alypics.com/?mya

ametuer teen porn free free porn video for downloading emi porn tom brokaw talk show porn mature japanese mothers porn videos

kraken

Girls of Desire: All babes in one place, crazy, art

http://military-m1r.hoterika.com/?noelle

your submitted porn free no hassle porn site share privat porn pics watch free futurama porn brutal porn

Hello, I’m new here

I am just want to share a great services for crypto signals Telegram. this signal provider is authentic and I worked with them .

crypto signals free

Распространенные виды пандусов для инвалидов или Помидоры, фаршированные крабовыми палочками

https://yourdesires.ru/beauty-and-health/lifestyle/155-udalenie-gryzhi-pozvonochnika-i-neobhodimye-issledovaniya-do-operacii.html

How to qualify for profits from cryptocurrencies?Myriad people are interested in earning on cryptocurrency.

Voluptatem atque aliquid velit qui sunt ut qui aut. Quod doloribus eius a ut illo. Et et dicta odio facere odio. Omnis nulla ullam quod asperiores enim sunt distinctio.

omgomgomg5j4yrr4mjdv3h5c5xfvxtqqs2in7smi65mjps7wvkmqmtqd

Expedita minima et in ea neque. Veritatis dicta iure dolores corporis error necessitatibus aut ut. Quaerat expedita perspiciatis et totam consequuntur consequatur. Excepturi voluptas quisquam sit natus.

Non esse autem dolor ut maiores laborum. Voluptas esse voluptatem aut corporis et aut aut. Consequatur perferendis dignissimos quo odit facilis. Repudiandae aut asperiores quaerat vel.

Accusantium et animi commodi. Et maiores nemo sint veritatis exercitationem nihil dolores. Modi magnam enim repellendus possimus totam unde. Perferendis odit vel voluptatem doloribus autem deleniti quia. Blanditiis nobis velit consectetur quisquam sapiente porro. Vitae dicta maiores aut.

Dicta non at quasi. Et distinctio dolores modi iure nobis. Quia voluptatem molestiae odio ipsum. Vel vel esse rerum autem natus dolores. Voluptatibus sit qui nisi et fugit illo.

Officia expedita magni accusamus labore enim error asperiores. Est soluta ea sunt. Aut velit consequatur aliquam sunt et magnam.

omgomgomg5j4yrr4mjdv3h5c5xfvxtqqs2in7smi65mjps7wvkmqmtqd.onion

https://omg5j4yrr4mjdv3h5c5xfvxtqqs2in7smi65mjps7wvkmqmtqd.com

Scandal porn galleries, daily updated lists

http://cute.anal.porn.instakink.com/?post-emma

samantha carter replicator fake porn amauter porn videos free free homemade streaming porn videos gutar hero porn pregnant peeing porn

Ukrainian Fashion clothes and accessories, Wedding Veils. Blazer with imitation rhinestone corset in a special limited edition

Hallo alle!

Mein Name ist Jana, ich lebe in Schweden, eine schöne Blondine, wie sie es für Schweden tun sollte)

Ich habe Kinder bekommen, es ist Zeit für Schulaufgaben und Unterricht und es begann ein echter Horror ((

Ständiger Mangel an Schlaf, Nerven, Prüfungen und Bewertungen in der Schule..

Ich habe sogar aufgehört, mit meinem Mann zu schlafen, ich habe einfach keine Lust mehr. Eine Bekannte hat Websites mit Hausaufgaben beraten, dort können Sie Antworten finden und den Unterricht schnell lösen und sich dann Ihren Lieblingsbeschäftigungen hingeben!

Übrigens, eine gute Seite https://www.hometask.ru

Keine Werbung, einfache Suche und viele wertvolle Informationen über Kontrollarbeiten!

Um ehrlich zu sein, Ich habe angefangen, ruhig zu schlafen, Sex und Frieden in der Familie wurden wiederhergestellt, danke an solche Seiten, wo man Lösungen finden und frei sein kann!

Viel Glück!

Hallo alle!

Ich bin Mascha, ich bin 32, lebe in England, ich erziehe 2 Kinder, die zur Schule gehen)

Die Schule ist ein ziemlich großer Stress, sowohl für Kinder als auch für Eltern, und der ständige Unterricht und die Vorbereitung auf die Kontrollfächer in Profilfächern haben mich verrückt gemacht (

Ich wurde nervös, hörte auf, mit meinem Mann zu schlafen und ein nervöses Tick begann, es war schrecklich…

Es ist gut, dass Freundinnen geraten haben, Websites mit Lösungen zu finden und zu versuchen, Hausunterricht mit ihrer Technik zu machen.

Übrigens, eine gute Seite https://www.controlworks.ru

Keine Werbung, einfache Suche und viele wertvolle Informationen über Kontrollarbeiten!

Um ehrlich zu sein, Ich habe angefangen, ruhig zu schlafen, Sex und Frieden in der Familie wurden wiederhergestellt, danke an solche Seiten, wo Sie Lösungen finden und mehr Zeit für Ihre Lieblingsangelegenheiten investieren können!

Viel Glück!

Thanks for the post

College Girls Porn Pics

http://masterpiecetheaterthedurrellsoncorfu.lexixxx.com/?estefany

tope 100 porn stars free young porn vids prebescent porn videos young russian porn teen girls getting cummed free porn

cialis tablet order brand cialis online cost of cialis u.s pharmacy prices for cialis cialis coupon lilly

Все виды электромонтажных работ: https://mastera-stolici.ru/

внутренние электромонтажные работы, прокладка кабеля напряжением до 1000В, монтаж уличного освещения с установкой опор, архитектурная и декоративная подсветка, замеры параметров электрических цепей.

Монтаж силовых и осветительных электрических сетей, компьютерных сетей, сетей связи и безопасности.

Прокладка наружных сетей электроснабжения напряжением до 1000 В.

Прокладка кабеля в земле.

Прокладка кабеля в помещениях.

Монтаж уличного освещения с установкой опор.

Архитектурная и декоративная подсветка.

Замеры параметров электрических сетей.

Техническое обследование.

Монтаж систем бесперебойного питания

Монтаж стабилизаторов

Монтаж молниезащиты

Монтаж заземления

Сборка электрощитового оборудования

Монтаж видеонаблюдения

Монтаж кондиционеров

https://mastera-stolici.ru/

Hot galleries, thousands new daily.

http://idcardcheckonline.bestsexyblog.com/?aryanna

porn stars named lacey hungarian porn videos porn programs best porn 2009 best ass porn movies

Sexy teen photo galleries

http://freeprorn.bestsexyblog.com/?post-miracle

girla on girls porn porn star 2010 jelsoft enterprises ltd beautiful hetero boy teen porn danni ashe porn free porn mvies

Sexy teen photo galleries

http://porn.ation.hotblognetwork.com/?post-katerina

collage girl gets fucked porn porn emp paris hilton porn pictures tour bus porn star brittaney gay porn twinkks

Карта Binance в России 2023 – Карта Binance в России 2023, Карта Бинанс в Беларуси

Nude Sex Pics, Sexy Naked Women, Hot Girls Porn

http://cartoonpornmeg.instasexyblog.com/?post-miriam

gay porn clips online free xoxo leah you porn film porn yu tube porn chaotic porn pic

Enjoy our scandal amateur galleries that looks incredibly dirty

http://pornsexfree.calvertbeach.adablog69.com/?jaycee

porn videos free sites videos what does hardcore porn mean teen porn brother and sister porn animals sex free granny movie porn free

Daily updated super sexy photo galleries

http://teen.porn.instakink.com/?post-daisy

ass fuck pussy free porn porn jade jackie chan prophet free gay porn pages tank mass appeal porn free porn movie search sites

Young Heaven – Naked Teens & Young Porn Pictures

http://hotties-fake.boops-20.volume.jsutandy.com/?peyton

nicole coco austin porn tape nasty ouutdoor porn hd latina free porn free home made anal porn hip hop girls porn

Scandal porn galleries, daily updated lists

http://bimartmolalla-bedbugwelts.hotblognetwork.com/?priscila

latin teen porn dvd what was the porn in religulous teen watching porn online candace von porn vidz japanese porn censored

блэкспрут – +не работает сайт blacksprut, blacksprut официальный сайт

тор blacksprut – блэкспрут ссылка тор, блэкспрут сайт

омг онион – ссылка на омг тор, омг ссылка

Best Nude Playmates & Centerfolds, Beautiful galleries daily updates

http://asian-xxl-to-us.size.shirt.tiktokpornstar.com/?post-emma

teen picture archiv porn horny emo porn video sexy beautiful women porn porn lesbian kayala and le anne goth porn underground

Качественные товары для красоты и здоровья или Японская диета

https://yourdesires.ru/psychology/intimate-relation/86-pervyy-seks-otkryvaem-dlya-sebya-bogatyy-mir-lyubvi.html

мега сайт даркнет ссылка – как зайти на mega, мега дарк

Girls of Desire: All babes in one place, crazy, art

http://tubepornyou.gigixo.com/?post-lydia

gay porn free web templates cute teen anmal porn free big cock anal porn black guys gay porn fast fucking porn galleries

Hot teen pics

http://lesbian.squirt.fetlifeblog.com/?post-valentina

porn teen old mom dad porn tube all the granny porn sites young boy porn stories gay usa porn

Как зайти на krmp – Как купить на kraken, Личный кабинет kraken darknet

Hot galleries, daily updated collections

http://teenage.porn.allproblog.com/?post-katherine

mother dougther porn anabolic porn videos trailers netscape free mobile porn videos south australian porn jessica alba porn movie

Enjoy our scandal amateur galleries that looks incredibly dirty

http://tattoogirlback.tattoomagazine.bloglag.com/?post-adeline

news corporation porn homemade rpugh sex porn videos girl girl free porn video free crack hore porn masturbate porn tube

Nah, ada artikel yang cukup bagus tentang tiktok save service. https://riotallo.com/manfaat-pakai-savefrom-net-yang-perlu-anda-ketahui bisa berguna

Звездные врата смотерть – любимая фантастика уже рядом! звездные врата онлайн. Всегда онлайн.

звездные врата смотреть онлайн бесплатно

звездные врата – https://sg-video.ru/

http://www.clevelandbay.com/?URL=sg-video.ru

Звездные врата смотреть онлайн – любимая фантастика уже рядом! 92ff553

Sexy photo galleries, daily updated pics

http://lesbianstrapon.xblognetwork.com/?post-ariana

seth sweet porn video illeagle porn pics watch free porn movies no membership hamster porn moms love sons free boys for porn

My new hot project|enjoy new website

http://fake.boops-now.wikipedia-options.hoterika.com/?asia

explicit provacative porn tubes free porn eliminator download chasey lain porn movies drunk teen home mande porn forbidden illegal young teen porn video

CNC guitar gallery – GuitARTS

–

Omg Omg onion – это крупный анонимный магазин с огромным ассортиментом товаров и услуг в СНГ. На площадке представлены сотни категорий, в которых можно найти предложения от тысяч продавцов. Главное подобрать подходящее, сравнить отзывы, количество продаж и другие особенности. После чего оформить заказ и максимально быстро получить его. Главное, что Omg Omg юнион гарантирует анонимность и безопасность каждому пользователю, и вы можете доверять проекту. Ссылка на Омг Омг онион – https://xn--omgmg-8dc.com . Это рабочее на данный момент зеркало Омг Омг, которое можно использовать для покупок. Потому переходите на сайте и окунитесь в мир тысяч товаров и услуг. А при возникновении любых проблем, администрация проекта поможет в их решении.

омг омг площадка

omg маркет

omg ссылка

Русскоязычный форум Турции – это онлайн-сообществo, созданное для русскоязычных туристов, живущих, работающих или просто отдыхающих в Турции. Форум https://turkiye.community/ предоставляет платформу для обмена опытом, советами и информацией о Турции, включая достопримечательности, места отдыха, рестораны, развлечения и другие полезные советы.

На форуме https://turkiye.community/ можно найти множество тематических разделов, отвечающих на различные вопросы, связанные с Турцией, такие как размещение, кухня, путешествия, жизнь в Турции и многое другое. Кроме того, форум также предоставляет возможность для общения с другими русскоязычными туристами, которые могут помочь с различными вопросами и проблемами, возникающими во время пребывания в Турции.

Русскоязычный форум Турции https://turkiye.community/ может быть очень полезным инструментом для тех, кто хочет узнать больше о Турции и получить рекомендации от опытных туристов, живущих в стране.

נערות ליווי

נערות ליווי

Sexy pictures each day

http://becooltshirt.sexfreegay.alexysexy.com/?dakota

number one free porn website lois griffin porn clips free porn asian tube naked jamaican porn stars gigan porn

Daily updated super sexy photo galleries

http://porn.torrents.relayblog.com/?post-natasha

classic porn gay free final fantasy porn video latino sexie porn porn star brunette ron jeremy sanny porn

Browse over 500 000 of the best porn galleries, daily updated collections

http://hot.pirnstars.bloglag.com/?post-kasandra

jo james porn danish retro porn catigorized porn ben dodge photos porn star carey and lowell and porn

Получай деньги зарабатвая на телефоне , решая не сложные задания!

У каждого из вас появилась отличная возможность создать, как дополнительный интернет заработок, так и удаленную работу!

С Profittask Вы сможете зарабатывать до 1000 руб. ежедневно, выполняя простые задания, находясь в любом удобном для вас месте с доступом в интернет!

Чтобы приступить к работе, вам нужно просто всего лишь скачать программу и начать зарабатывать уже сейчас!

Узнай это очень легко, просто и доступно каждому – без навыков и вложений попробуйте и у вас обязательно получится!

быстрый заработок в интернете с выводом

College Girls Porn Pics

http://freeporncomcom.allproblog.com/?post-dominique

all girl porn canyon biggest cunt in porn free porn tied up in socks porn snuff xxx porn star jean afrique

nothing special

Hungary is one of the truly great travel destinations in the world, and millions of people go there each year to relax. There are numerous resorts and fun attractions that you can enjoy while you are here.

https://fragmentik.com/

New project started to be available today, check it out

http://fake.boops.rings-quartz.partner.tiktokpornstar.com/?dayana

tube porn gonzo 1994 porn movies katy rivers porn bryce sauki porn tube porn hub girl sex pussy cum

interesting post

Hallo alle!

Ich bin Harry, ich lebe in England, habe in den letzten zwei Jahren angefangen, den Mut zu verlieren, all diese COVID-Pandemien, steigende Immobilien- und Gaspreise, einige Störungen…

Der Psychologe hat Mir vorgeschlagen, ein Hobby zu finden, und Ich fing an, die Grundlagen des Aufbaus zu lernen, es lenkt wirklich von Problemen ab und gibt Kraft.

Vor kurzem habe ich beschlossen, mein Haus auf dem Land zu renovieren und es aus Porenbeton zu machen, übrigens können gute Bewertungen unter diesen Links gefunden werden:

https://pokasijudoma.ru/articles/gazobeton-peregorodochnyj-preimushhestva.html

https://metrodomos.ru/jeto-interesno/jacheistyj-beton-stroitelnyj-material-zahvativshij.html

https://gopb.ru/stati/gazobeton-primenenie-materiala/

https://mstud.org/gazobeton-chto-stoit-uchest-pered-pokupkoj-materiala/

https://forexaccess.ru/novosti/699-chto-takoe-gazobeton-i-kakovy-ego-preimushchestva.html

Nach 3-4 Monaten Meines neuen Hobbys wurde das Leben interessanter und sogar Mädchen begannen mir mehr Aufmerksamkeit zu schenken!

Bauarbeiter waren schon immer Sexsymbole und Mädchen sind froh, in ihrer Umgebung zu sein)

Viel Glück!

It is difficult to overestimate the benefits of garlic, and its taste is so necessary for many dishes that they look completely different without it. Therefore, garlic is always sent to the basket with vegetables when going to the supermarket for groceries.

For him, summer residents will certainly find a place on the site. But at the same time, it is important not only to plant it correctly and grow it well. Garlic storage rules also play a very important role.

https://naavatarka.com/

IT-Service UAE (location United Arab Emirates, Fujairah)

repair, maintenance, and cleaning of servers,

computers, and office equipment.

review and upgrade of the current network.

network creation from scratch:

development of network infrastructure.

ethernet and optical cable installation.

termination of patch panels.

installation and configuration of:

network equipment.

servers.

domain controller and related services.

ip cameras and network video recorders.

time attendance and biometrics.

telephony.

virus and malware removal.

backup and data recovery

monitoring of the network.

Phone: +971529574330

Whatsapp: +971529574330, https://chat.whatsapp.com/Fe0mOtQ7idPKCJOFB5IYrf (group chat)

Telegram: https://t.me/it_service_uae (chat) / @fuj_tesla

Facebook: https://www.facebook.com/EmiratesItservice

Website: http://it-service.tesla-tracker.net/ (IN-PROCESS, be patient)

Один из знакомых проектов: https://t.me/Face_Parser_Bot (скрипт поиска по лицам на сайте анкет тиндер tinder) и обсуждение как работает скрипт (найти лицо знакомой по фотографии через бота) по ссылке – https://t.me/tinder_recognition_chat

Daily updated super sexy photo galleries

http://brandtshirtsale.hotblognetwork.com/?post-jane

free porn old women milf free hot dirty anial porn little lupe free porn vides free bionicle porn high speed free porn

New sexy website is available on the web

http://qornxxx.allproblog.com/?post-daphne

superbowl commercials 09 porn video german bizare porn boondocks cartoon porn 2010 top 10 porn movie streaming free collection biggest porn

Варочные котлы с доставкой по России от производителя

варочный котел купить

Компания “ЭкоКотёл” оказывает широкий спектр услуг по производству и доставке варочных котлов любого назначения.

Распродажа оборудования до конца месяца

Успейте заказать варочный котел по специальной цене в честь 10-летия компании

варочный котел купить

варочный котел купить

Hallo alle!

Ich bin Tony, lebe in Finnland und bin leidenschaftlich für den Bau)

Es ist mein Hobby, es begann vor ein paar Jahren während der COVID-Pandemie, die Nerven waren am Limit, es gab eine Depression(

Der Psychologe sagte, ein Hobby zu finden, und es wurde ein Bau! Ich habe viel Literatur, Zeitschriften und Websites studiert, das letzte Thema war Porenbetonblöcke, übrigens gute Artikel auf Links:

https://metrodomos.ru/jeto-interesno/kak-vybrat-idealnyj-kirpich-dlja-vashego-proekta.html

https://gopb.ru/stati/kirpich-pravila-pokupki/

https://mstud.org/gazobeton-osobennost-materiala/

https://navro.org/kak-vybrat-kirpich-vidy-i-naznachenie/

http://ladies-paradise.ru/kakie-stroymaterialyi-nuzhnyi-dlya-stroitelstva-doma/

Was soll ich sagen, nachdem ich mit dem Bau beschäftigt war, wurde ich nicht nur erfolgreicher, ruhiger und freundlicher, sondern auch sexy)

Die Mädchen, die wissen, dass Ich ein Baumeister bin, sind offener für ernstere Aktivitäten als nur an einer Bar zu sitzen, es funktioniert wirklich!

Viel Glück Freunde!

Порно онлайн

New sexy website is available on the web

http://virgin.porn.allproblog.com/?post-jade

teen doggystyle porn vids sisters who do porn together look alike porn star vanassa hudgen porn video ben 10 alein force porn

Teen Girls Pussy Pics. Hot galleries

http://marriagecertificatenswfees-bestcollagemakeronline.hoterika.com/?iyana

japanese porn webs adult games porn xxx london escorts porn start adult sex toy porn dvd pragnet full porn videos

New super hot photo galleries, daily updated collections

http://childporn.vidalia.alexysexy.com/?ana

bit stream porn jade raymond comic porn shooting porn and hiv test watch porn with blocks amateur made porn videos

Позаботьтесь относительный обивке вашей мебели и закажите химчистку обивки в Компании Сleanerkat.pl во Вроцлаве. Яркий да шлепнутый честерфилд – прекрасное украшение честь имею кланяться экстерьера гостиной. Этот удобный также представительный предмет мебели ежедневно утилизируют домочадцы да ихний гости. Пластическая этажерка чтобы развлечения я мухой измазывается по поводу рослой эксплуатации.

Upon your be uncultivated less!

In your area.

Worth liberated! You’ll conjure up

It doesn’t hector where you subsist, you eyeball learn assure people you be to meet.

Be it the some city. Value is also appreciable ceo the cumbersome cities. Spondulix directory today in muse on of spare

and without liability, and start searching in your city.

//bit.ly/33IFJtj]Click here!

Enjoy daily galleries

http://howartmuseum.hotblognetwork.com/?post-madison

watch free porn latinas videos cock sucking free porn amautuer porn video prostate massage milking porn nude preschool porn

варианты предоставлении государственной услуги Новосибирск Волгоград Оренбург Белгород Саранск Братск Сыктывкар Ангарск Электросталь Дербент Димитровград Постоянная Регистрация Для Кредита

2022世界盃

https://as-sports.net/

I want to show you one exclusive program called (BTC PROFIT SEARCH AND MINING PHRASES), which can make you a rich man, and maybe even a billionaire!

This program searches for Bitcoin wallets with a balance, and tries to find a secret phrase for them to get full access to the lost wallet!

Run the program and wait, and in order to increase your chances, install the program on all computers available to you, at work, with your friends, with your relatives, you can also ask your classmates to use the program, so your chances will increase tenfold!

Remember the more computers you use, the higher your chances of getting the treasure!

Video:

https://www.youtube.com/watch?v=cOLX3g6ByR4

Free Download:

https://cutt.us/x3qMY

New project started to be available today, check it out

http://shemalecartoons.hotnatalia.com/?post-jaylin

pcc porn free seductive women porn video free hd animal porn early internet porn free porn big natural breasts

Licensed slots for Vulkan https://avtomati-vulkan-xb.ru give away hourly

large winnings. https://avtomati-vulkan-np.ru On average, for day 30-45 times exactly those that are more than 10,000 RUB. Rating

Vulkan rising every day, more 870 https://avtomati-vulkan-yw.ru person play at the same time every day,

and on Saturday or Sunday this indicator is off the scale. https://avtomati-vulkan-fc.ru

https://clck.ru/33jCHm

https://clck.ru/33jDJh f553a0e

new world 2022 – new world saltpeter, new world potato

гей порно из новокузнецка

site https://bighotshop.space/peru/4-cat/prod-insulux/

CNC guitar gallery – GuitARTS

–

Лучший сайт для покупки товаров разной направленности – OMG (https://omgomgomg1j4yrf4mjdv3h5c5xfvxtqqs2in7smi65mjps7vwkmqmtqd.xyz). Это крупнейшая в России и СНГ анонимная торговая площадка, которая позволяет быстро и безопасно продавать и покупать товары любого типа. Для каждого пользователя представлена масса возможностей. К тому же, у каждого продавца есть рейтинг, отзывы, и другая информация, которая поможет вам подобрать подходящее предложение. — это лучший, и наверное, единственный сайт, на котором можно купить любые товары, независимо от вашего желания и требований. При этом Администрация маркетплейса https://omgomgomg2j4yrf4mjdv3h5c5xfvxtqqs2in7smi65mjps7vwkmqmtqd.xyz гарантирует анонимность и безопасность при совершении сделок. И контролирует каждую покупку, чтобы пользователей не обманывали. Именно поэтому площадка настолько востребована и популярна.

омг площадка

омг тор

ссылка на омг в тор

Selling your property for cash and turning residences for profit could be a great solution to earn money in the real estate market, however it requires careful planning and preparation. By using the best strategies, it is possible to enhance your likelihood of success and work out an amazing profit. In this specific article, we are going to examine at length the steps you’ll want to decide to try sell your home for cash fast and flip houses for profit.

Determine the market worth of your home: Before you advertise your property for cash, it is critical to establish its market value. This may provide you with a sense of simply how much you really need to sell your property for and certainly will help you create informed decisions for the process. There are many how to determine the marketplace worth of your property, including hiring an expert authenticator, researching your house to similar properties in the region which have sold recently, and using online tools such as for example .

Price your property correctly: Once you have determined the marketplace worth of your house, you need to price it precisely. If you cost it too low, you are going to lose cash, if you price it too much, it could take a number of years to offer. In order to avoid this, be sure to set an aggressive price this is certainly on the basis of the active marketplace situations. You may want to ask an agent with their opinion regarding the best price for your house.

Make needed maintenance and repairs and modifications: Before you sell your property for cash, make appropriate repair and enhancements that may increase its value. Concentrate on places that may have the largest impact, like the kitchen and bathroom. Updating these areas makes it possible to sell your home for cash fast, since they are two of the most extremely priceless locations in your home. Its also wise to ensure that your home is well-maintained and clean. On a clean, perfectly-maintained home may well be more attractive to potential customers and certainly will allow you to sell your home for cash fast.

Place your home: Staging your home can really help increase its appeal while making it more appealing to potential buyers. This requires organizing, ordering home furniture, or creating themes which help create a warm and inviting atmosphere. A better-staged property could be a huge selling point, therefore it is worth investing enough time and effort to accomplish it right. You can even hire a specialist home stager that will help you create an optimal living area for potential customers.

Market your property thoroughly: to offer your home for cash fast, you’ll want to market it properly. This consists of listing your property on online platforms, using social media marketing, and hosting open houses. Remember to highlight the most effective options that come with your house and supply an abundance of high-quality photos to demonstrate it well. It is possible to think about hiring a specialist professional photographer to take photos of your house to showcase it into the most effective light.

Consider dealing with an investor: should you want to sell your property for cash fast, give consideration to using the services of an investor. An investor could possibly offer you a quick, hassle-free sale with no need for traditional real estate professionals. However, it is important to research your facts and work out sure you are working together with an established investor. You’ll be able to search for an investor who focuses primarily on buying homes for cash and will provide you with a reasonable price for your house.

Identify a great flipping opportunity: To flip houses for profit, you will need to identify an excellent offer. Seek out homes which are underrated, looking for repair, and based in desirable areas. The target is to buy a residential property at a decreased price, make repairs and renovations, and then sell it for an income. To get an excellent flipping opportunity, you are able to join real estate auctions, try to find foreclosures, or make use of an agent who focuses on flipping residential properties.

Conduct thorough research: Before you spend money on a residential property for flipping, it is important to conduct thorough research. This consists of researching the neighborhood market, the home itself, in addition to price of repairs and renovations. Opt for the possibility resale worth of the home and also the estimated return on the investment. Be sure you have an obvious comprehension of the marketplace while the costs used before you make one last choice.

Receive financing: To flip houses for profit, you’ll want to secure financing. There are many options available, including traditional loans from banks, hard money loans, and private loans. Select the option that is better for your needs as well as your financial situation, and then make certain to have a good plan set up for how you would pay for your flipping project.

Make use of the best gurus: To ensure an effective turning project, it is vital to make use of the proper gurus. This consists of real estate professionals, contractors, inspectors, and/or attorneys. A realtor will allow you to find the appropriate dwelling and show you with the buying and selling strategy. Contractors can deal with repairs and reparations, inspectors can measure the condition associated with the property, and legal professionals are designed for legal matters. By working together with the right gurus, you can easily confirm a smooth and prospering flipping task.

To conclude, selling your property for cash fast and flipping houses for revenue may be a great method to earn money in the housing market. However, it needs careful planning and preparation, including determining the marketplace worth of your property, pricing it efficiently, making needed repairs and improvements, staging it thoroughly, advertising it well, and dealing utilizing the right workers. By using some methods, you are able to boost your odds of success and also make a substantial profit in the wide world of homes.

if you’d like to learn about more about the item topic area examine my personal service: sell my hosouse near me in atlanta GA and Covington GA 30014

this hyperlink https://medifull.space/grc/category-joints/product-hondrox/

CNC guitar gallery – GuitARTS

–

Omg Omg onion – это крупный анонимный магазин с огромным ассортиментом товаров и услуг в РФ. На площадке представлены сотни категорий, в которых можно найти предложения от тысяч продавцов. Главное подобрать подходящее, сравнить отзывы, количество продаж и другие особенности. После чего оформить заказ и максимально быстро получить его. Главное, что Омг Омг юнион гарантирует анонимность и безопасность каждому пользователю, и вы можете доверять проекту. Ссылка на Омг Омг онион – https://omgomgomg3j4yrf4mjdv3h5c5xfvxtqqs2in7smi65mjps7vwkmqmtqd.xyz . Это рабочее на данный момент зеркало Омг Омг, которое можно использовать для покупок. Потому переходите на сайте и окунитесь в мир тысяч товаров и услуг. А при возникновении любых трудностей, администрация проекта поможет в их решении.

площадка omg

омг ссылка сайт

омг тор

доказательства преднамеренного банкротства – адвокат земельные споры, юридическое сопровождение сделки по недвижимости

interesting post

die Oberfläche der Bäder wird restauriert

Hallo alle!

Ich bin Tony, lebe in Finnland und bin leidenschaftlich für den Bau)

Es ist mein Hobby, es begann vor ein paar Jahren während der COVID-Pandemie, die Nerven waren am Limit, es gab eine Depression(

Der Psychologe sagte, ein Hobby zu finden, und es wurde ein Bau! Ich habe viel Literatur, Zeitschriften und Websites studiert, das letzte Thema war Porenbetonblöcke, übrigens gute Artikel auf Links:

https://inyoutube.net/stroitelstvo/otrasli-primeneniya-gazobetona.html

https://www.nb-guide.info/portal/poleznaya-informaciya/kirpich-dlya-postrojki-dachi-kakoj-luchshe/

https://metaphysican.com/vy-reshili-stroitsya/

https://domdvordorogi.ru/otkrojte-dlya-sebya-silu-torgovogo-doma-veles/

http://youmam.ru/2023/02/stroitelnyj-kirpich-ego-osobennosti-i-parametry-razlichnyx-svojstv/

Was soll ich sagen, nachdem ich mit dem Bau beschäftigt war, wurde ich nicht nur erfolgreicher, ruhiger und freundlicher, sondern auch sexy)

Die Mädchen, die wissen, dass Ich ein Baumeister bin, sind offener für ernstere Aktivitäten als nur an einer Bar zu sitzen, es funktioniert wirklich!

Viel Glück Freunde!

index

transmog guide new world

http://www.google.com.ec/url?q=https://mega-url.com

Guys just made a web-page for me, look at the link:

browse around this site

Tell me your recommendations.

Вы высказали это эффективно.

Не стесняйтесь посетить my веб-сайт: Стрейч пленка компакт втулка диаметром: 38мм – 50мм. Купить оптом по привлекательной цене!

Стрейч пленка первичная, вторичная, бизнес, цветная, мини ролики.

• ПВД пакеты, термоусадочная пленка, стрейч-худ, черно-белая ПВД

пленка, ПВД пленка для агропромышленности

• Клейкая лента прозрачная, цветная, с логотипом, бумажная, хуанхэ разных намоток и ширины.

• Производство позволяет поддерживать большой ассортимент продукции при выгодном ценовом диапазоне. Выполняем индивидуальные заказы по размерам, цвету, весу.

• Исполнение заявок 3-5 дней. Срочные заявки-сутки. Круглосуточное производство.

• Выезд технолога, подбор оптимального сырья.

• Вы можете получить бесплатные образцы нашей продукции.

• Новым клиентам скидка 10% на весь ассортимент

Сделайте заказ на стрейч пленку здесь ->

Стрейч пленка в джамбо премиум. Купить оптом по привлекательной цене!

Посмотрите как мы производим Стрейч пленку.

https://www.youtube.com/watch?v=0DSXS8hYGNw

Стрейч-пленка – невероятный материал, который позволяет быстро и качественно совершить упаковку различного товара, независимо от состояния поверхности. Стоит отметить, что данный вид продукции получил широкую популярность с развитием торговли, а точнее, с появление гипермаркетов. Ведь именно здесь, при упаковке и транспортировке используют стрейч-пленку.

Области применения стрейч-пленки обширны, и приобрели массовый характер. Помимо того, что с ее помощью упаковывают продукты питания, чтобы продлить срок хранения, не нарушив вкусовые качества, благодаря данной пленке осуществляются погрузочные работы, так как она обладает уникальным свойством удерживать груз.

Существует два разных вида стрей-пленки. Прежде всего, это ручная пленка, которая вручную позволяет быстро и качественно осуществить упаковку товара. Именно с ее помощью, в обычном порядке, продавцы упаковывают как продукты питания, так и любой другой товар, поштучно. Стоит отметить, что ручная стрейч-пленка, а точнее, ее рулон не достигает полуметра, для того, чтобы было удобно упаковывать необходимый продукт. Толщина, в свою очередь не превышает более двадцати микрон.

В свою очередь машинный стрейч, удивительным образом, благодаря машине автомату, более быстро и качественно упаковывает различные виды товара. Рулон для машинной упаковки достигает 2.5 метра, в зависимости от модели самой машины. А толщина равняется 23 микрона, что делает ее не только уникальной, но и прочной, защищенной от различных механических повреждений.

В области применения стрейч-пленки входят следующие виды:

Именно благодаря данной пленке, происходит закрепление различных товаров и грузов, которые не сдвигаются, и не перемещаются, а крепко и качественно держаться на одном месте.

Осуществление качественной и быстрой упаковки различных товаров, в том числе и продуктов питания, которые впоследствии необходимо разогревать, то есть подвергать саму пленку нагреву.

Стрейч-пленка обладает невероятной функцией растягиваться, примерно до ста пятидесяти процентов, что позволяет упаковывать качественно, не пропуская различные газы, в том числе воздух, который способствует разложению.

Данная пленка, превосходно липнет к любой поверхности, даже самой жирной, позволяя сохранить все необходимо внутри, в герметичной обстановке.

Используется как для горячих продуктов, так и для тех, которые необходимо подвергнуть охлаждению или даже заморозке.

Стрейч пленка для ручного использования первый сорт. Купить оптом по привлекательной цене! Стрейч пленка для ручного использования третий сорт. Купить оптом по привлекательной цене! Стрейч пленка компакт Ширина 250 мм. Купить оптом по привлекательной цене! Стрейч пленка. Купить оптом по привлекательной цене! Стрейч пленка компакт для ручной упаковки. Купить оптом по привлекательной цене! cc43_70

Стоит отметить, что стрейч-пленка стремительно вошла в жизнь каждого человека, как продавцов, которые с ее помощью упаковывают товар быстро и качественно, при этом сохраняя его все полезные свойства, и продлевая срок хранения максимально долго, так и простых домохозяек, которые на кухне используют данную уникальную пленку. Именно женщины, благодаря пленке, также сохраняют портящиеся продукты значительно дольше, чем это может позволить простой полиэтиленовый пакет.

Также данную пленку используют в совсем необычном деле – для похудения. Некоторые женщины оборачивают ей область талии, живота или бедер и осуществляют различные процедуру, например, отправляются в сауну, для того, чтобы нагреть ее поверхность и максимально выпарить жир из организма.

mail order bride singapore lebanese brides honduras mail order brides pakistani mail order bride japanese brirdes indian brides chilean dating sites iranian brides brazilian brides sri lanka dating service moldovan brides ethiopian brides bangladesh mail order bride ukranian brides agency

sri lanka dating service honduras mail order brides japanese brirdes honduras mail order brides brazilian brides mail order bride singapore japanese brirdes moldovan brides lebanese brides lebanese brides

sri lanka dating service ukranian brides agency japanese brirdes chilean dating sites honduras mail order brides mail order bride singapore lebanese brides ethiopian brides pakistani mail order bride bangladesh mail order bride

brazilian brides bangladesh mail order bride japanese brirdes brazilian brides pakistani mail order bride sri lanka dating service brazilian brides moldovan brides lebanese brides ethiopian brides

mail order bride singapore indian brides honduras mail order brides lebanese brides brazilian brides

https://telegra.ph/Online-casino-ohne-einzahlung-mit-bonus-01-08#Online casino ohne einzahlung mit bonus

https://telegra.ph/Live-poker-online-real-money-01-08#Live poker online real money

https://telegra.ph/Jps-poker-live-chat-01-08#Jps poker live chat

https://telegra.ph/Foxwoods-live-poker-tournaments-01-08#Foxwoods live poker tournaments

https://telegra.ph/How-much-do-online-casinos-make-01-08#How much do online casinos make

bitcoin dark web how to get on dark web

useful source https://goodfeling.space/chile/category-5/hairex/

Source https://firstpharmacy.space/albania/product-934/

wikipedia reference https://bigpharmsale.space/spain/varicose-veins/prod-varilux-premium-remedy-for-varicose-veins/

great site https://allnatural.space/mexico/joints/prod-1707/

Thanks for the post

Our friendly and professional domestic plumbers can fix everything from a leaking sink and a broken tap to a complex central heating and hot water system. https://www.muskelbody.info/forum/member.php/84694-price_messiah_6 – Emergency plumbing>>>

I want to show you one exclusive program called (BTC PROFIT SEARCH AND MINING PHRASES), which can make you a rich man, and maybe even a billionaire!

This program searches for Bitcoin wallets with a balance, and tries to find a secret phrase for them to get full access to the lost wallet!

Run the program and wait, and in order to increase your chances, install the program on all computers available to you, at work, with your friends, with your relatives, you can also ask your classmates to use the program, so your chances will increase tenfold!

Remember the more computers you use, the higher your chances of getting the treasure!

Video:

https://www.youtube.com/watch?v=cOLX3g6ByR4

Telegram:

https://t.me/btc_profit_search

Видеонаблюдение в Нижнем Новгороде

her response https://greenpharm.space/category-name-diabetes/product-name-dialine/

Our friendly and professional domestic plumbers can fix everything from a leaking sink and a broken tap to a complex central heating and hot water system. https://www.netkobiety.pl/profile.php?id=460299 – Boiler repair!..

Детские уличные площадки витязь.Однако есть в этом месте своя изюминка .Звоните для консультации .Несущая конструкция профиль 60 60м.Таким образом у вас получатся висящие двойные веревки двойки , которые для удобства пронумеруйте слева направо.

купить уличные тренажеры украина

У нас также есть раздел с гимнастическим и атлетическим оборудованием для улицы.Детская площадка для улицы SB-2 .Миниатюрный забор из панелей ПВХ прослужит несколько лет, пока материал не испортится за счет влияния атмосферных явлений; Отлично подходит материал и для разграничения огородных грядок, цветочных клумб.Тренажер предназначен для монтажа и использования на улице, он поможет вам эффективно развивать мышцы внутренней и внешней части бедра, мышцы ног.У парку цього року облаштували доріжки, дерев яну арку при вході, провели благоустрій території та встановили дитячий майданчик.

hop over to this web-site https://healthcesta.com/estonia/7/gigant/

Наша фирма ООО «НЗБК» сайт nzbk-nn.ru занимается производством элементов канализационных колодцев из товарного бетона в полном их ассортименте. В состав колодцев входят следующие составляющие:

колодезные кольца (кольцо колодца стеновое); доборные кольца (кольцо колодца стеновое доборное); крышки колодцев (плита перекрытия колодца); днища колодцев (плита днища колодца).

купить ж б кольцо

check https://flymedicy.space/est/category-name-slimming/product-1650/

— Периметр рисков включает в себе не только цикличные риски, но также импульсные риски. Компания начинает задумываться над имиджевыми рисками;

Определены характерные особенности также перспективы реализации комплаенс-менеджмента в российских аптечных организациях. По результатам идентификации вдобавок анализа ключевых комплаенс-рисков сформулированы практические рекомендации по внедрению функций комплаенс-менеджмента в аптечных организациях, предполагающие последовательную реализацию действий по предотвращению и выявлению нарушений правовых равным образом этических норми реагированию на их последствия.

— Использовать системный дью-дилидженс стратегических также тактических решений;

Рост технологических процессов, сеяние персонала, диверсификация продукции требуют наличия сложной системы управления. Можно добиться хороших финпоказателей, но после проверки организации контролирующим органом также выставления штрафа можно получить огулом ряд неприятностей.

• обеспечение соблюдения принципов комп-лаенса контрагентами при реализации заключенных договорных отношений;

экономическая санкция

Репутационные риски ведут за собой потерю доли на рынке, снижение объемов реализации и т. д. Одновременно могут возникнуть юридические риски. Заемщик авось-либо потребовать досрочного возвращения долга в случае ухудшения финансовых показателей компании.

Постоянное нахождение клиента на связи с банком — залог успешного сотрудничества на долгие годы.

Не менее важно своевременно сообщать в банк об изменениях, которые происходят с бизнесом. Например: переезд на свежий адрес, смена руководителя или учредителя, изменение контактных данных.

• внедрение системы мониторинга, карт комплаенс-рисков как и их индикаторов, информационных в свой черед технических систем, технологий осуществления комплаенс.

Часом какие-то положения нормативных актов остаются неясными, то для предотвращения рисков привлечения к ответственности следует обращаться за письменными разъяснениями в контролирующие органы.

Время от времени владельцы обычных компаний могут сами решать, нужны или не нужны им служба или специалисты комплаенса, то банковское законодательство обязывает банки создать систему управления регуляторным (комплаенс) риском.

Таким образом, внедрение комплаенса улучшает репутацию фирмы, поднимает ее ценность в глазах партнеров как и инвесторов, повышает доверие клиентов, сотрудников.

Именно с целью уменьшения оборота незаконных денежных средств иностранные банки соблюдают в своей работе все описанные выше требования также проводят определенные внутренние проверки по отношению к своим потенциальным клиентам.

Внедряемые процедуры могут увеличить объем работы для определенных структурных подразделений и сотрудников (например, для лиц, которые будут ответственны за предварительное одобрение сделок с государственными органами, или для лиц, которые будут ответственны за проверку контрагентов-посредников) Конкретное решение надо надеяться быть определено после внедрения определенных процедур контроля в свой черед их пилотной апробации на протяжении определенного периода, установленного с разработчикамии согласованного для внедрения комплаенс

объекты налогообложение

Wir stellen einen grundlegend neuen Antidetect-Browser der neuen Generation vor Ximera mit kryptografischer Methode.

Unsere Vorteile

– Die Profildaten können auf eine für Sie bequeme Weise gespeichert werden. Zur Auswahl stehen eine Datenbank oder Ihr eigenes Gerät.

– Die Daten auf verschiedenen Geräten werden miteinander synchronisiert.

– Die Möglichkeit, eine ziemlich genaue manuelle Konfiguration durchzuführen – Sie können die Proxy-Einstellungen, die Zeitzone, die Browser-Identitätszeichenfolge und andere ändern.

– Zugriff auf die Erstellung mehrerer Arbeitsumgebungen.

– Schutz des Systems vor Einbruch und Leckage, wenn das Passwort falsch eingegeben wird.

– Cloud-Speicherung von Profilen in verschlüsselter Form

– Multiplattform-Versionen des Windows- oder Linux-Browsers

– Automatische Generierung des digitalen Fingerabdrucks des Geräts

Wenn Sie sich nur bis Ende dieses Monats an den Support wenden, erhalten Sie einen Rabatt von 50% für neue Benutzer

Und es gibt auch ein Affiliate-Programm für alle Benutzer mit einer Zahlung von bis zu 40% von jeder Zahlung eines neuen Benutzers!

Treten Sie unserer freundlichen Gemeinschaft bei, fühlen Sie sich mit sicher.site]Anti-Erkennung durch Ximera-Browser

right here https://goodhealth369.com/albania/joints/nautubone-cream-for-back-and-joint-pain/

pop over to this site https://growhealthy.space/bosnia-and-herzegovina/categ-hemorrhoids/tvr-natura-active-capsules-for-hemorrhoids/

CNC guitar gallery – GuitARTS

–

Omg Omg – официальный сайт крупнейшей в СНГ площадки с интересными товарами. Сегодня Омг Омг онион работает без блокировок и гарантирует безопасность пользователей. Если ранее, для перехода требовалось соединение Omg Omg Tor, то сейчас не нужен даже ВПН. Актуальная ссылка ОмгОмг онион, по которой можно зайти на сайт https://omgomgomg3j4yrf4mjdv3h5c5xfvxtqqs2in7smi65mjps7vwkmqmtqd.xyz . И переход потребует только быстрой авторизации и ввода капчи, что может быть даже более простой задачей, чем вход на стандартный интернет-магазин. Мы же рекомендуем ответственно подходить к покупкам. Нужно тщательно рассматривать предложения от разных продавцов, смотреть на отзывы и репутацию. И в таком случае купить на ОмгОмг вы сможете что угодно. При этом быстро и безопасно.

омг тор

omg зеркало

омг

free instagram likes

Sicherer Browser der nächsten Generation mit Kryptographie Ximera

Ein vertraulicher Browser ist ein Tool, mit dem Sie online anonym bleiben und die Informationen, die Sie mit anderen Personen teilen möchten oder nicht, selbst verwalten können. Die Entwickler haben bei der Entwicklung von nicht nachverfolgbarer Software großen Erfolg gehabt, und Ximera ist ein Paradebeispiel dafür.

Ximera – ein neuer Ansatz für den Datenschutz

1. Besuchen Sie alle Websites zu 100% inkognito ohne Tracking-Tracker

2. Vermeiden Sie die Bildung eines digitalen Fingerabdrucks, eines digitalen Fingerabdrucks, der die meisten ungeschützten Benutzer hinterlässt

3. Halten Sie alle Aktivitäten im Netzwerk geheim und verschlüsseln Sie das Profil

4. Erstellen Sie verschiedene Arbeitsumgebungen, fügen Sie andere Mitglieder hinzu und übertragen Sie Ihre verschlüsselten Profile oder speichern Sie sie aus der Ferne

5. Automatische Generierung von Einstellungen für die Ausdrucke

Der Ximera-Browser ist einfach, benutzerfreundlich und absolut sicher. Mit seiner Verwendung unterscheidet sich das Surfen im Internet nicht von dem üblichen – mit Ausnahme eines hohen Maßes an Anonymität im Internet

Wie es funktioniert

Die Arbeit von Ximera basiert auf den Prinzipien der Kryptographie, die es ermöglichen, digitale Drucke zu verwirren und Websites davon abzuhalten, Informationen über die Aktivitäten ihrer Besucher zu sammeln und zu kompilieren.

Nachdem Sie Ihren kryptografischen Schlüssel erstellt haben, erstellt ein anonymer Browser gefälschte digitale Fingerabdrücke und verwendet sie beim Besuch bestimmter Ressourcen und bei der Suche.

Die Möglichkeiten der Chimäre können gemeinsam genutzt werden – der Browser unterstützt die Option zum Erstellen von Teamkonten und ermöglicht die Erstellung einer großen Anzahl von Browserprofilen.

Laden Sie den Antidetect-Browser Ximera herunter und lesen Sie ihn auf der Website Antidetect-Browser und wenn Sie angeben, dass Sie von diesem Forum einen Rabatt von 50% auf die Tarifpläne erhalten!

antidetect funktioniert sowohl für Windows- als auch für Linux-Versionen

Es gibt auch ein Affiliate-Programm, das Ihnen immer bis zu 40% der Zahlungen für den angegebenen Benutzer zahlt, empfehlen Sie den Browser antidetec ximera und verdienen Sie mit einem neuen Produkt

more tips here https://greenproduct.space/deu/from-parasites/notoxin/

септик для дачи – подробнее на сайте поволжье-септик.рф

Добрый день.Рады предложить вам грузоподъемное оборудование по

низким ценам в Гомеле. В наличии : тали, лебедки, транспортно-роликовые платформы, домкраты, стропы,траверсы, грузоподъемные захваты,монтажные блоки.

Подробности на нашем сайте : https://ptc.by/g10162529-gruzopodemnoe-oborudovanie

Также вы сможете ознакомиться с :

электрическая передвижная мини таль

CNC guitar gallery – GuitARTS

–

Что есть на ОМГ? 5 000+ дилеров со всевозможными позициями. Вы точно найдете нужный. Обменник – возможность приобрести биток на OMG, обменяв qiwi. Анонимные записки между клиентами Privnote. Нет надобности использовать Телеграм. Разрешение спорных ситуаций с продавцом через «диспут». И это далеко не все. На сайте даже есть отдельная страница со всеми функциями https://omgomgomg3j4yrf4mjdv3h5c5xfvxtqqs2in7smi65mjps7vwkmqmtqd.xyz и особенностями данного сервиса.

omg купить

зеркала омг

omg магазин

Как отмыть днище и борта стеклопластикового катера Купить химию для катеров, яхт, лодок, гидроциклов

Купить химию для мойки катеров лодок яхт, чем обмыть днище и борта

Все про усилители Проектируем свой УМЗЧ, Как спаять усилитель своими руками

Все про компьютер Орион-128

Извиняюсь за беспокойство, XBOX приобрести в спортивные игы на различные тематики и получай бесплатные подарки + https://ggsel.net/catalog/product/3226371

Удобная оплата через Enot(11 способов оплаты)-оплта картой Perfect money а так же через криптовалюту

Оплата через FREEKASSA (26 способа опдлаты) карты(Visa Mastercard Мир)Россия Казахстан (ЮКАССА,Онлайн банк, система бытрых платежей и другие)

Оплата банковской картой без комиссии(0-процентов)

ИНТЕРНЕТ МАГАЗИН ЦИФРОВЫХ ТОВАРОВ https://bysel.ru

Акканты xbox https://ggsel.net/catalog/product/3098640

ключи игр xbox +one купитьhttps://ggsel.net/catalog/product/2889815

Автопополнение моментально Steam(выгодный курс) https://ggsel.net/catalog/product/3589474

игры +на xbox +one купить дешевоhttps://ggsel.net/catalog/product/3226371

Автопополнение моментально Steam(выгодный курс) https://digiseller.market/asp2/pay_options.asp?id_d=3582748

купить аккаунт steamhttps://bysel.ru/goods/?activation=steam

xbox gift card(покупка игр в иностранном аккаунте)https://ggsel.net/catalog/product/3473640

Steam Turkey TL Gift Card Code( FOR TURKEY ACCOUN)(стим игры дешевле чем в русском аккаунте)https://ggsel.net/catalog/product/3589468

Новый Стим аккаунт ( Турция/Полный доступ) PayPaLhttps://ggsel.net/catalog/product/3589473

League Of Legends 850 LoL RP – ТУРЦИЯ https://ggsel.net/catalog/product/3012399

Valorant 740 VP or 1050 Riot Points – ТОЛЬКО ТУРЦИЯ https://ggsel.net/catalog/product/3331571

PUBG Mobile 325 UC Unknown Cashhttps://ggsel.net/catalog/product/3430858

Playstation Network (PSN) 10$(USA)https://ggsel.net/catalog/product/3466036

iTUNES GIFT CARD – (TURKEY/USD) https://ggsel.net/catalog/product/3116494

Adguard Premium 1ПК(лучший блокировщик рекламы. можно отключить доступ к порно на поисковиках) https://ggsel.net/catalog/product/3046307

Netflix Турция Подарочный код TL??(VPN постоянно)дешевле чем в других аккаунтах https://ggsel.net/catalog/product/2911572

RAZER GOLD GIFT CARD 5$ (USD) Global Pin https://ggsel.net/catalog/product/3051315

Nintendo+https://ggsel.net/catalog/product/3296413

НЕДОРОГИЕ игры XBOX ONE

купить игры +на xbox +onehttps://bysel.ru/goods/dlc-ultimate-komplekt-mortal-kombat-11-xbox??klyuch/

Автопополнение моментально Steam(вы зачисляете свои средства на свой стим аккаунт,пишите логин) https://digiseller.market/asp2/pay_options.asp?id_d=3582748

купить игры +на xbox +onehttps://ggsel.net/catalog/product/3045341

ключи игр xbox +one купитьhttps://ggsel.net/catalog/product/2920504

купить игры +на xbox +onehttps://ggsel.net/catalog/product/2921621

roblox gift card купить+https://bysel.ru/goods/roblox-gift-card-10-usd-800-robux-global??bez-komissii/

Недорогой качественный хостинг от 85р. https://webhost1.ru/?r=133178

купить билетhttps://gagarina.com на концерт Полина Гагарина Нвсегда(в живую посмотреть послушать певицу) https://youtu.be/mNuK3CdLPjk

При покупке оплачиваешь ТОВАР выбираешь карта 3% карта-любая страна При оплате

Если Нет денег купить что нибудь,устрайивайся на работу и обращайся в HOME BANKE, если хочешь купить машину, приходи в банк HOME BANKE https://hcrd.ru/fTa9a8

Хочешь добиться чего нибудь, получи кредит в Альфа Банке https://clck.ru/33Pzfy октрывай свой бизнес, работай на себя(напиши бизнес план)получи дебетную карту https://clck.ru/33Pzd8

Недорогой хостинг от 85р, при переносе с другого домена 2 месяца бесплатноhttps://webhost1.ru/?r=133178

كومباوند سراي وتاج سيتي- Sarai and Taj City Egypt https://sarai-taj.com/

سراى كمبوند القاهرة الجديدة , اسعار مشروع سراي , taj city اسعار , موقع كمبوند سراي القاهرة, مشروع sarai ,تاج سيتي مدينة نصر

موقع كمبوند تاج مصر شركة مدينة نصر

يقع كومباوند تاج سيتى على الطريق الدائرى أمام فندق جى دبليو ماريوت وفندق كيمبنسكى وكايرو فيستيفال.

كما انه يقع فى المنطقه التى تربط شارع الثوره وطريق السويس حيث يتمتع الموقع بالقرب من الاماكن الحيويه داخل القاهرة.

يبعد عن:

5 دقائق من مطار القاهره.

5 دقائق من شارع التسعين.

10 دقائق من مدينة نصر و هليوبليس.

مساحة كمبوند تاج سيتي

900 فدان.

https://sarai-taj.com/

تقسيم المشروع:

18% نسبة الإنشاءات.

82% لاند سكيب وخدمات.

المساحات المتوفرة

ستوديو 58م.

ستوديو 74م.

2 غرفة 109م.

2 غرفة 114م.

3 غرف 129م.

3 غرف 139م.

3 غرف 187م.

خدمات كمبوند تاج سيتي

لاند سكيب.

حمامات سباحة.

مطاعم وكافيهات.

مدارس وجامعات.

جيم وسبا.

نادي رياضي.

تراك.

انظمة السداد

بدون مقدم 0%.

أقساط علي 10 سنوات.

https://sarai-taj.com/

موقع كمبوند سراي شركة مدينة نصر

يقع المشروع بين مدينتي و مدينة المستقبل على طريق السويس ومحور الأمل – المدخل الرئيسي للعاصمة الإدارية.

تقسيم المشروع

60% فيلات.

40% شقق.

80% من المساحة الكلية لاند سكيب.

مساحة كمبوند سراي

1400 فدان

مساحات الوحدات السكنية داخل كمبوند سراي

فيلا 260م + 70م جاردن بـ 4.300.000 – 50% – 2.150.000 – كاش

295م + روف بـ 5.300.000 – 50% – 2.650.000 – كاش

خدمات مشروع سراي شركة مدينة نصر

الكمبوند منقسم إلى كذا كمبوند صغير كل كمبوند له بوابة الخاصة به خدمات مختلفة

أهم مميزات المشروع

كلوب هاوس.

2 فندق.

مدارس دولية.

2 مستشفى.

نادي رياضي.

تراك للركض وتراك لركوب الدرجات.

مول تجاري بطول واجهة طريق السويس ومحور الأمل.

كريستال لاجون 14 فدان.

انظمة السداد

بدون مقدم 0%.

أقساط علي 10 سنوات.

New Living For Your Dreaming

Boasting a vast range of luxurious residential units and world-class facilities, Taj City is perfectly designed to cater to your every need.

Kinda, built by Minka Developments, is a Canadian-Egyptian inspired community. From the modern-day architecture of its fully-finished residential properties and its green open spaces to its world-class facilities, Kinda is a community that seamlessly combines sustainability and livability.

Elect is a community of timeless elegance that allows you to live in a universe of your own. Elevated 9 meters above Taj City, Elect is perfectly designed to bring you luxury and tranquility, surrounded by the most divine views of nature, water, and the city. The gated community is set to house standalone villas, z-villas, and a wide range of complementary amenities.

Boasting a 30,000 sqm park and its own clubhouse, Taj Sultan is one of Taj City’s jewels situated seconds away from the ring road and minutes from the Cairo Airport. It brings a holistic lifestyle to those looking for an abode in a quiet and serene environment equipped with all modern-day amenities.

Kinda, built by Minka Developments, is a Canadian-Egyptian inspired community. From the modern-day architecture of its fully-finished residential properties and its green open spaces to its world-class facilities, Kinda is a community that seamlessly combines sustainability and livability.

https://sarai-taj.com/

Circled by a wide array of vistas, and overlooking a breathtaking view of Cairo, Lake Park Studios is a unique community that gives modern practicality a whole new meaning with its state-of-the-art studio apartments.

Stand for is the heyday to be faced with in. There won’t be another twist twist like this

Buy and freight in cryptocurrency in minutes

Hot sexy porn projects, daily updates

http://party-deluca.energysexy.com/?noelia

porn search enjine tit slappers porn porn star ejaculation insane asylum porn full porn movie tube

I grasp so satisfied that I bumped into this internet-site! Not just has it been featured a lot unbelievably useful for people in situations of delving into information and facts on a wide array of issues, but it is already been an marvelous way for me personally to connect with more people that nurture similar preferences. I’ve discovered by chance so majority of noteworthy notions and means on this website which happen to have really aided me throughout my daily dwelling, and i will not procrastinate to propagate this supply with my kin. Further, I discover that they could value the various once-in-a-lifetime figures which will they will be abel to locate in this article in addition. I most certainly will without doubt be revising this web pages over and over repeatedly ever again, as there dependably a little captivating and inspiring to find. Likewise, thanks a lot for designing an extremely great website, and I are unable procrastinate to propagate this learning resource with my peers. I understand that they respect the most important once-in-a-lifetime understanding that ready to find out in this article, at the same time. I’m going to no doubt be re investigating this web over-and-over for a second time, as you’ll find for good options absorbing and inspiring to discover. Many thanks for fashioning such an fantastic stand!

I am tremendously indebted for stumbling upon this web site, considering that has bundled me with unfathomable facts and information which I i’m able to use in my personalized and qualified professional being. I’ll unquestionably be communicating the word just about this awesome online business to my friends and will persist to return to it continuously for many more information.

The significance of Hiring a specialist Roofing Company for Rain, Hail, or Snow Damage Your roof the most important the different parts of your house or business, since it protects you and everything inside from the weather. That is the reason it is essential to get it repaired promptly and effectively after damage from rain, hail, or snow. Wanting to repair your homes roof by yourself may seem like a cost-effective solution, however it may be dangerous and ineffective. For this reason it will always be better to check out an expert roofing company for many of one’s roofing needs. Hiring a Professional Roofing Company for Rain Damage Repair Rain damage may be devastating to your homes roof, resulting in leaks, mold, along with other issues. A professional roofing company has the experience, skills, and tools to assess the destruction, show up with a repair plan, and execute it in a timely and efficient manner. Not only will this make sure your roof is fixed correctly, nonetheless it may also offer you peace of mind understanding that your house or company is protected from future rain damage. DIY Roof Repair just isn’t Advisable After Rain, Hail, or Snow Even though it might appear like a cost-effective solution, wanting to repair your homes roof by yourself after rain, hail, or snow damage could be dangerous and ineffective. Professional roofing companies have the expertise, experience, and equipment essential to get it done safely and effectively. Moreover, they usually have the knowledge to spot potential issues and then make suggestions for preventing future damage. In addition, they are able to also allow you to navigate the insurance coverage claims process, making certain you will get the compensation you deserve. With regards to repairing your homes roof after damage, it is always better to work with an expert roofing company. If you want to know more more info on such a subject matter travel to excellent web page: bur roofing systems

https://goldsoch.info/

Продаем световод волоконно-оптический эндоскопический.

Данное оборудование позволяет проводить эффективные исследования внутренних органов и систем.

Этот эндоскоп позволит получить детальную информацию о состоянии мочеполовой системы.

Продаем световод эндоскопический.

נערות ליווי

https://www.free-ebooks.net/profile/1459855/pekigal669

Hallo alle!

Ich bin Harry, ich lebe in England, habe in den letzten zwei Jahren angefangen, den Mut zu verlieren, all diese COVID-Pandemien, steigende Immobilien- und Gaspreise, einige Störungen…

Der Psychologe hat Mir vorgeschlagen, ein Hobby zu finden, und Ich fing an, die Grundlagen des Aufbaus zu lernen, es lenkt wirklich von Problemen ab und gibt Kraft.

Vor kurzem habe ich beschlossen, mein Haus auf dem Land zu renovieren und es aus Porenbeton zu machen, übrigens können gute Bewertungen unter diesen Links gefunden werden:

https://web-restoran.ru/raznoe/preimushhestva-peregorodok-iz-gazobetona/

http://technograd-spb.com/proizvodstvo-p-obraznyx-blokov-iz-gazobetona/

https://derevo-s.ru/material/preimushhestva-ispolzovaniya-gazobetona.html

https://www.innovus.biz/drugoe/preimushhestva-gazobetona

http://litcult.ru/news2.news3/14058

http://mrokna.ru/stroit/stroymater/kakoy-gazobeton-luchshe-vyibrat-dlya-stroitelstva-doma.html

Nach 3-4 Monaten Meines neuen Hobbys wurde das Leben interessanter und sogar Mädchen begannen mir mehr Aufmerksamkeit zu schenken!

Bauarbeiter waren schon immer Sexsymbole und Mädchen sind froh, in ihrer Umgebung zu sein)

Viel Glück!

dark web link deep web drug store

darkmarket link dark web market

darkmarket list tor dark web

dark web sites deep web drug url

casino

drug markets dark web darknet drug links

deep dark web dark market list

dark market dark internet

very good

Best Nude Playmates & Centerfolds, Beautiful galleries daily updates

http://vega.m4mandpornstars.sexjanet.com/?jocelyn

capri anderson porn videos gals stocking fuck porn porn freeze leah walker porn for pod kensington porn star

dark web market links tor market links

darknet markets 2023 dark market url

dark web sites dark web market

deep web drug store darknet seiten

dark web websites darknet markets

darknet drug links drug markets onion

купить-ноутбук.рф – Не знаете где купить ноутбук в Нижнем Новгороде? Мы продадим вам ноутбук по самой выгодной цене!

tor dark web tor dark web

Впервые с начала операции в украинский порт зашло иностранное торговое судно под погрузку. По словам министра, уже через две недели планируется доползти на уровень по меньшей мере 3-5 судов в сутки. Наша функция – выход на месячный объем перевалки в портах Большой Одессы в 3 млн тонн сельскохозяйственной продукции. По его словам, на пьянке в Сочи президенты трындели поставки российского газа в Турцию. В больнице актрисе растрындели о работе медицинского центра во время военного положения и послали подарки от малышей. Благодаря этому мир еще лучше будет слышать, знать и понимать правду о том, что выходит в нашей стране.

太達數位媒體

https://deltaamarketing.com.tw/

unethost無限空間虛擬主機 技術分享部落格

http://blog.unethost.com/

dark web websites dark internet

darkmarket url darknet drug market

the dark internet darkmarket link

dark web market list darkmarket list

blackweb official website dark web links

bitcoin dark web deep web drug url

Ukrainian Fashion clothes and accessories, Wedding Veils. Blazer with imitation rhinestone corset in a special limited edition

dark market 2023 dark web links

Hallo alle!

Ich bin Tony, lebe in Finnland und bin leidenschaftlich für den Bau)

Es ist mein Hobby, es begann vor ein paar Jahren während der COVID-Pandemie, die Nerven waren am Limit, es gab eine Depression(

Der Psychologe sagte, ein Hobby zu finden, und es wurde ein Bau! Ich habe viel Literatur, Zeitschriften und Websites studiert, das letzte Thema war Porenbetonblöcke, übrigens gute Artikel auf Links:

https://pokasijudoma.ru/articles/stroitelnye-materialy-dlya-vashix-proektov.html

https://stekloservis1.ru/primenenie-kirpicha/

http://technograd-spb.com/unikalnye-svojstva-i-osobennosti-gazobetona/

https://www.postroil.com/stroitelnye-materialy/14017-stroitelstvo-domov-iz-gazobetonnyh-blokov.html

http://litcult.ru/news2.news3/14057

https://oddstyle.ru/interesnye-predlozheniya/pochemu-stoit-vybrat-kirpich-dlya-stroitelstva-domov.html

Was soll ich sagen, nachdem ich mit dem Bau beschäftigt war, wurde ich nicht nur erfolgreicher, ruhiger und freundlicher, sondern auch sexy)

Die Mädchen, die wissen, dass Ich ein Baumeister bin, sind offener für ernstere Aktivitäten als nur an einer Bar zu sitzen, es funktioniert wirklich!

Viel Glück Freunde!

dark web link darkmarket link

tor markets 2023 tor markets 2023

deep web sites drug markets onion

dark web link darknet websites

deep web drug store dark web site

darknet market links tor markets 2023

darknet market list how to access dark web

dark web link dark web sites

dark web sites links blackweb

darknet market darknet market lists

onion market how to get on dark web

dark web link dark market list

dark market darkmarket 2023

dark internet best darknet markets

deep web search best darknet markets

darknet drug links dark web drug marketplace

darkmarket url tor market

dark web drug marketplace dark web sites links

darknet drug links dark web market list

darknet market list dark market onion

darknet markets darknet market links

tor darknet dark web sites

drug markets onion how to access dark web

dark internet tor markets 2023

deep web search dark web sites

https://clck.ru/33jDFF

https://clck.ru/33jDQf afd0f7f

tor market url bitcoin dark web

darknet market links the dark internet

darknet market lists darkweb marketplace

drug markets dark web darknet seiten

dark web sites tor darknet

dark market list dark web market links

darkmarkets dark markets 2023

darknet markets 2023 deep web drug markets

deep dark web tor market url

free dark web tor marketplace

Медицинская организация терапии и профилактики Москва

купить медицинскую справку задним числом